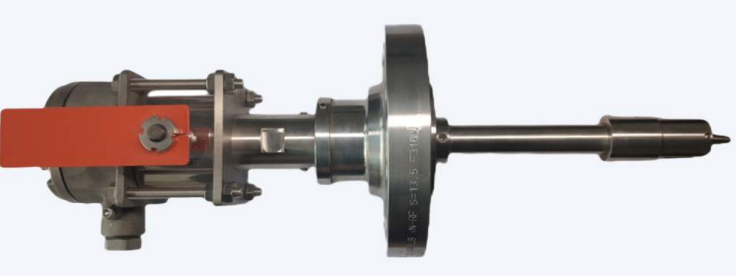

pigs for pipeline cleaning

Pipeline cleaning pigs, often simply called “pigs,” are specialized devices designed to facilitate the maintenance and cleaning of pipelines in various industries, including oil and gas, water utilities, and food processing. These innovative tools play a crucial role in ensuring the efficiency and longevity of pipeline systems.

- Design: Pigs come in various shapes and sizes, designed to fit different pipeline diameters.

- Material: Common materials include polyurethane, rubber, and metal, depending on the application.

- Functionality: They can clean, inspect, and help with product separation in pipelines.

Types of Pipeline Cleaning Pigs

- Foam Pigs: Lightweight and compressible, used for gentle cleaning.

- Polyurethane Pigs: Durable and effective for a range of cleaning tasks.

- Magnetic Pigs: Equipped with magnets to capture ferrous debris.

- Scraper Pigs: Feature blades for removing heavy deposits.

- Bristle Pigs: Use bristles for scrubbing the pipeline walls.

Applications

- Oil and Gas: Essential for maintaining flow and preventing corrosion.

- Water Utilities: Helps in maintaining the cleanliness of water supply lines.

- Food Industry: Ensures hygiene in processing lines.

Benefits

- Enhanced Flow: Reduces friction and blockage, improving flow rates.

- Cost-Effective Maintenance: Minimizes the need for manual cleaning and reduces downtime.

- Prolongs Pipeline Life: Regular cleaning can prevent damage and extend service life.

Considerations

- Compatibility: Choose a pig suitable for the specific fluid and pipeline conditions.

- Cleaning Schedule: Regularly assess the need for cleaning based on usage and buildup rates.

1. Smart Pig Technology

Integrate sensors and IoT technology into pigs to monitor pipeline conditions in real-time. These smart pigs can send data back to operators about the level of buildup, temperature, and even corrosion, allowing for more informed maintenance decisions.

2. Customizable Pig Designs

Develop modular pigs that can be tailored for specific tasks. For instance, allow users to swap out cleaning components based on the type of debris or the specific conditions of their pipeline.

3. Eco-Friendly Cleaning Agents

Incorporate biodegradable cleaning agents into the design of pigs. As the pig moves through the pipeline, it could release these agents to help break down buildup, making the cleaning process more environmentally friendly.

4. Gamification of Pipeline Maintenance

Create a gamified system for operators where they can track pig runs and cleaning performance. Offer rewards or recognition for teams that achieve the best cleaning metrics or most efficient operations.

5. Collaborative Pigging Solutions

Develop a platform where companies can share their experiences and data on pigging techniques and technologies. This could help identify best practices and innovative uses for cleaning pigs across different industries.

6. Artistic Pipeline Designs

Consider how pigs can be used in artistic expressions—such as creating sculptures from decommissioned pigs or showcasing the journey of a pig through a pipeline in a creative installation. This could raise awareness about pipeline maintenance and engineering.

7. Virtual Reality Training

Use VR simulations for training staff on how to operate and maintain pipeline cleaning pigs. This can provide hands-on experience without the risks associated with actual pipeline work.

Exploring these innovative approaches could significantly enhance the efficiency and appeal of pipeline cleaning solutions! If you’d like to dive deeper into any of these ideas, just let me know!

![]()

![]()

![]()

![]()