Pig launchers and receivers are critical components in pipeline systems, designed to introduce and retrieve pigs (pipeline inspection gauges) for cleaning, maintenance, and inspection. Understanding the key parts of these systems is essential for ensuring their effective operation and longevity.

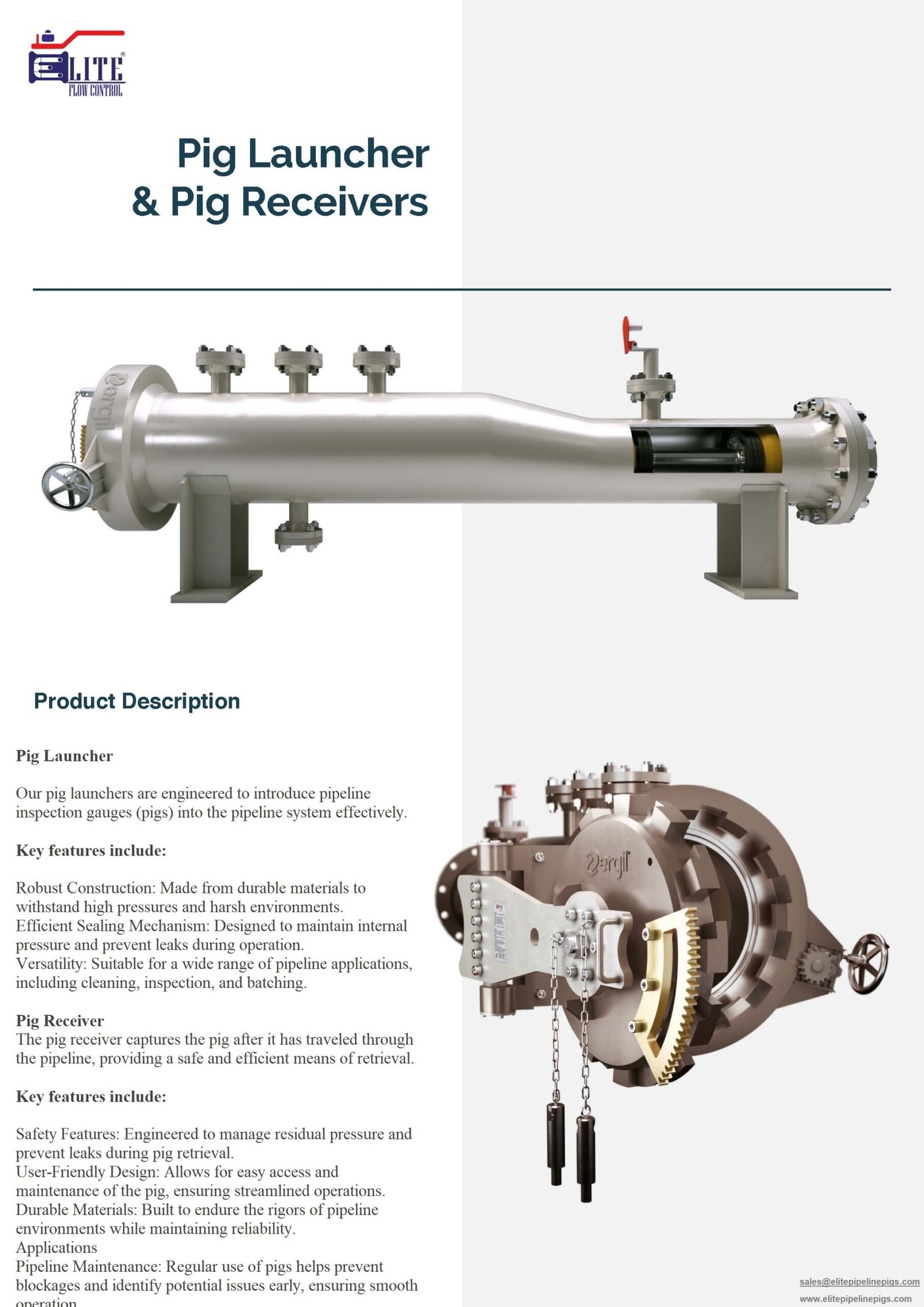

Pig Launcher

Our pig launchers are expertly designed to facilitate the introduction of pipeline inspection gauges (pigs) into various pipeline systems. Positioned at the start of pipeline segments, our launchers feature robust construction with advanced sealing mechanisms that maintain internal pressure and prevent leaks. Engineered for both durability and efficiency, our pig launchers support a range of tasks, including cleaning, inspecting, and product batching, making them essential for maintaining pipeline integrity.

Pig Receiver

Our pig receivers complement our launchers and are strategically designed to safely capture pigs after they complete their pipeline journey. Located at the pipeline’s end, these receivers are built to manage residual pressure effectively, ensuring safe retrieval of the pig for maintenance and inspection. Equipped with safety features that prevent leaks and control pressure release, our pig receivers enhance the overall safety and reliability of your pipeline systems.

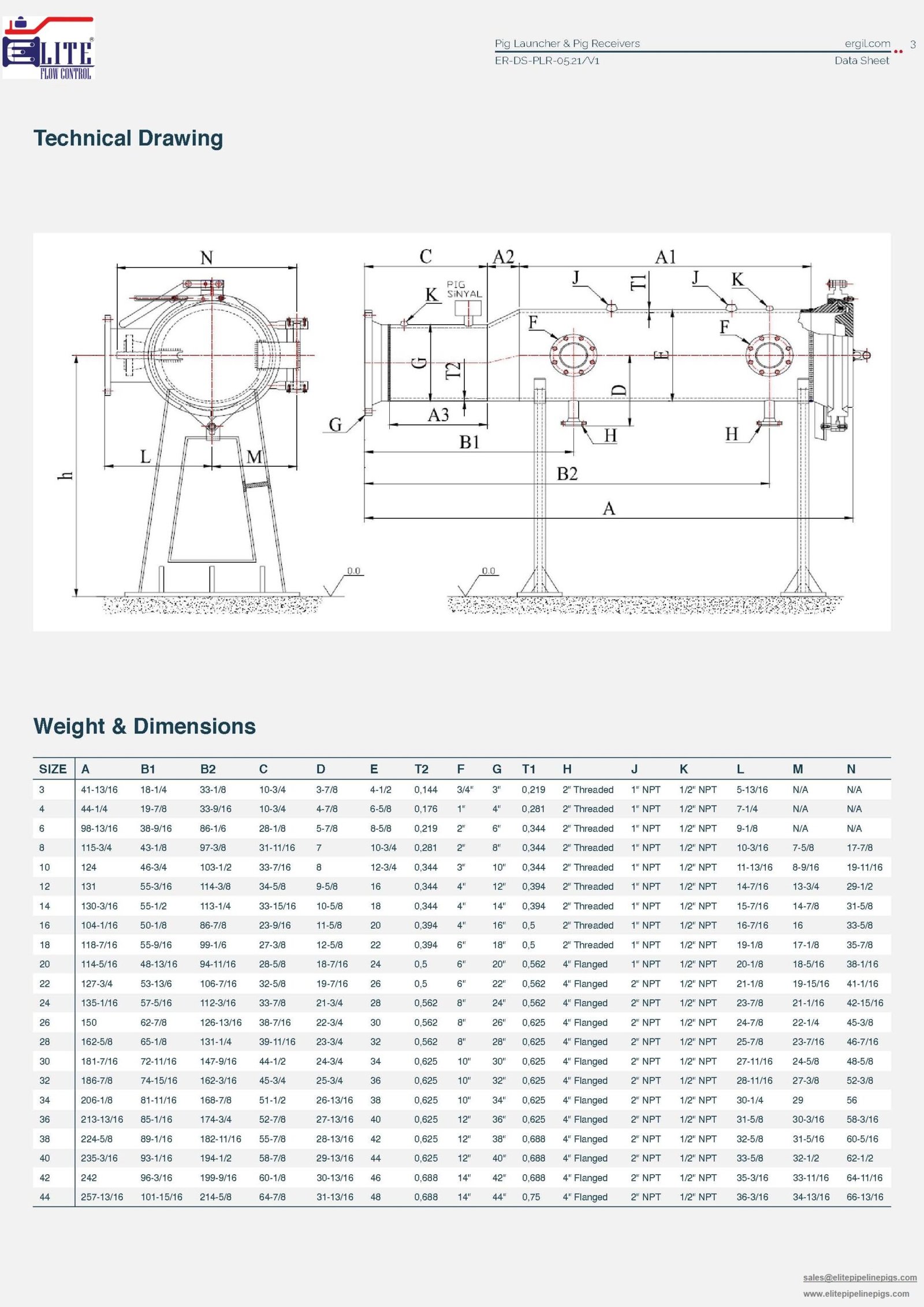

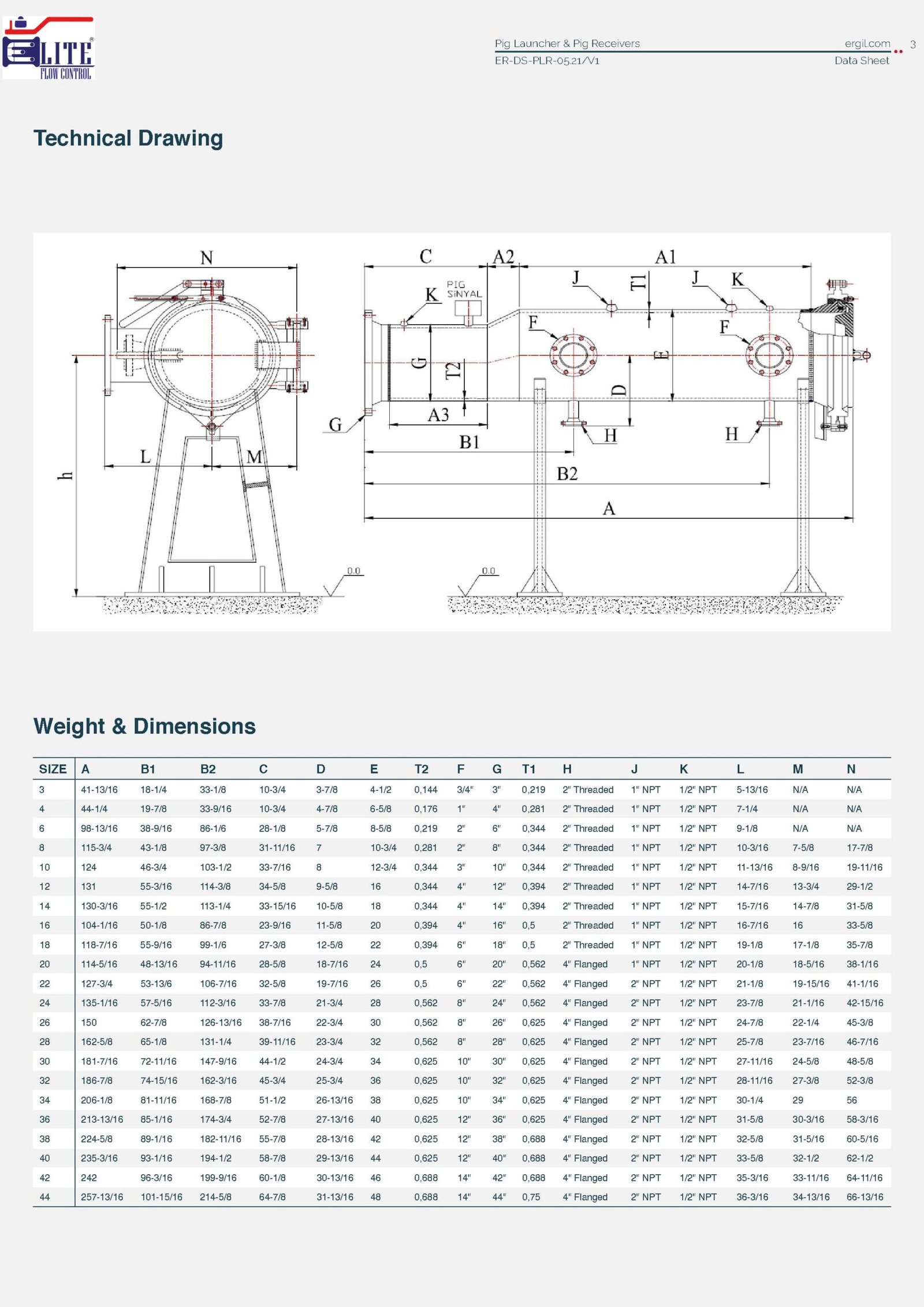

Datasheet

![we provide high-quality pipeline pig launchers and receivers that are designed to optimize pipeline operations, ensuring safety, efficiency, and long-term reliability. Our products are engineered with the following advantages: Custom Solutions: Tailored pig launchers and receivers to meet your pipeline's unique specifications and operational needs. Durable & Reliable: Built to withstand the toughest pipeline conditions, ensuring extended operational lifespans. Global Expertise: Serving industries worldwide with expert knowledge and support, ensuring your pigging operations are successful. Safety First: Advanced safety features that protect your pipeline, personnel, and assets during pigging operations. Industries We Serve: Oil & Gas Petrochemical Water & Wastewater Chemical Processing Power Generation Food & Beverage For more information or to request a quote for pipeline pig launchers and receivers, contact us today at [Your Company Name]! We are dedicated to providing the most efficient, reliable, and cost-effective solutions for your pipeline maintenance needs.](https://elitepipelinepigs.com/wp-content/uploads/2024/10/pig-launcher-receiver_Page_2-1-scaled.jpg)

Key Parts of Pig Launchers:

Launcher Body: The main housing that contains the pig during launching. It is designed to withstand high pressures and provide a secure environment for the pig.

End Caps: These are fitted at both ends of the launcher to ensure a sealed environment, preventing any leaks during the launching process.

Pig Guide: A device that helps direct the pig into the pipeline smoothly, minimizing the risk of damage.

Pressure Relief Valve: A safety feature that helps release excess pressure in the launcher, preventing potential hazards.

Launch Port: The opening through which the pig is introduced into the pipeline, often fitted with a closure mechanism to maintain pressure.

Key Parts of Pig Receivers:

Receiver Body: Similar to the launcher, the receiver body collects the pig after it has traveled through the pipeline.

Discharge Port: The opening where the pig exits the receiver, allowing for easy retrieval and inspection.

End Caps: Used to seal the receiver body, maintaining pressure and preventing leaks.

Pig Trap: A mechanism within the receiver that helps to capture and hold the pig securely upon its arrival.

Pressure Gauge: This indicates the pressure within the receiver, allowing operators to monitor conditions effectively.

Benefits of Using Quality Parts:

- Enhanced Safety: High-quality components minimize the risk of leaks and ensure safe operations during pig launching and retrieval.

- Improved Efficiency: Reliable parts help streamline pipeline maintenance and inspection processes, reducing downtime.

- Longevity: Durable materials and construction contribute to the long-term performance of pig launchers and receivers, ultimately lowering maintenance costs.

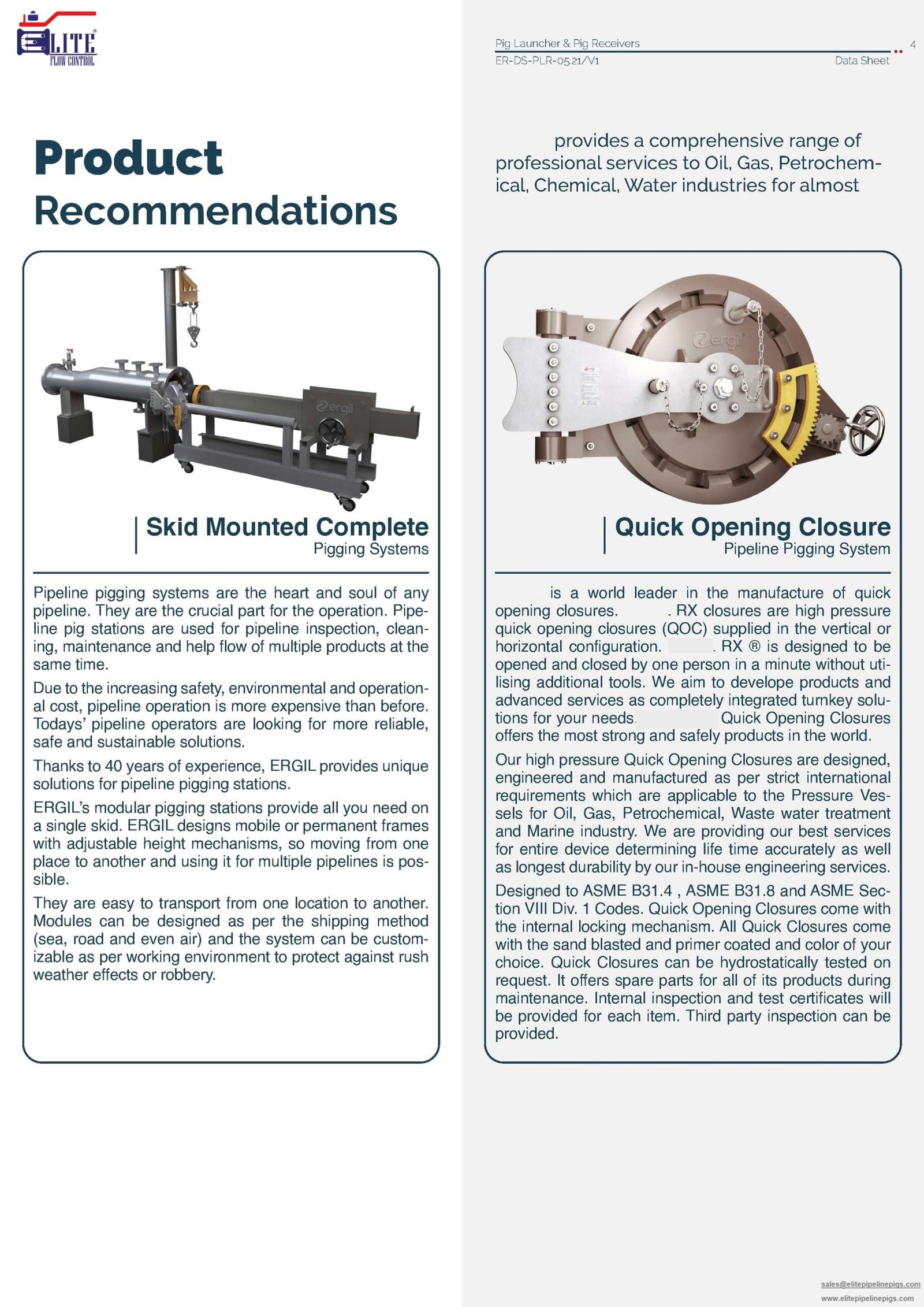

Why Choose Us?

Elite Pigs we specialize in supplying high-quality pig launcher and receiver parts tailored to meet the needs of the oil, gas, and chemical industries. Our commitment to quality, innovation, and exceptional customer service makes us a trusted partner in pipeline operations.