STEEL MANDREAL CLEANING PIGS

We are specializing in providing high-quality pipeline cleaning mandrel pigs designed to enhance the efficiency and longevity of pipelines across various industries. Our mandrel pigs are engineered to meet the highest standards of durability and performance, making them an essential tool for effective pipeline maintenance.

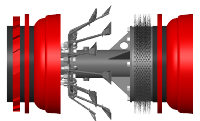

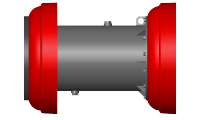

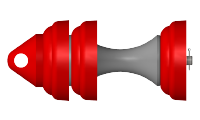

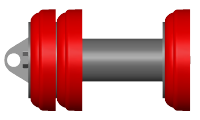

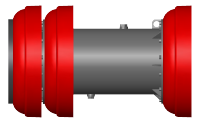

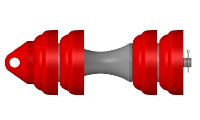

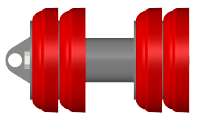

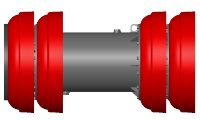

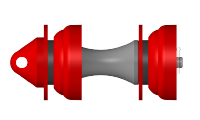

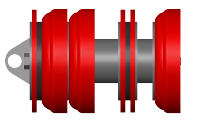

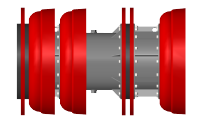

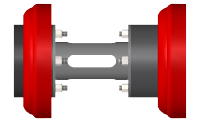

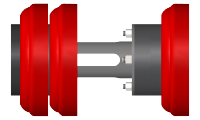

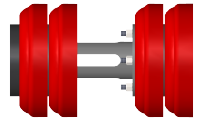

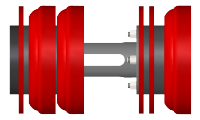

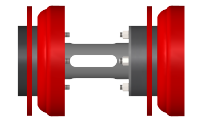

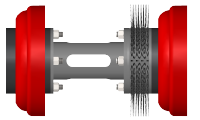

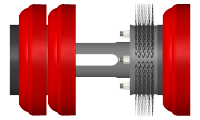

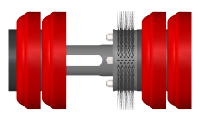

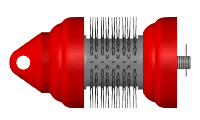

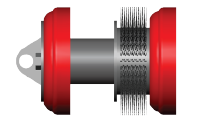

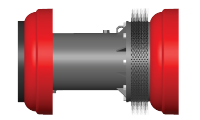

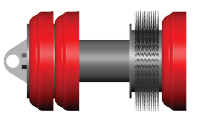

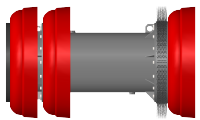

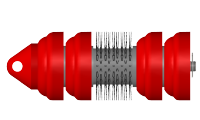

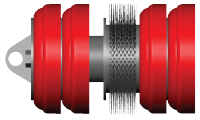

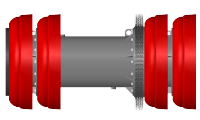

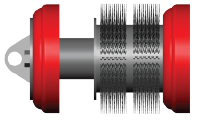

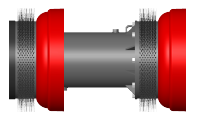

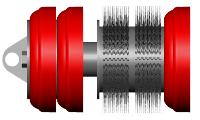

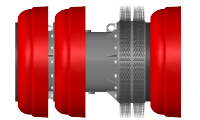

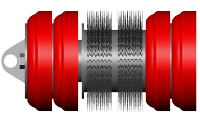

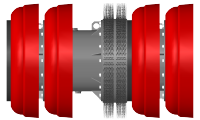

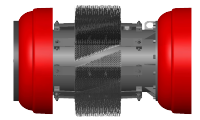

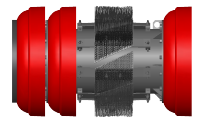

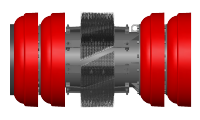

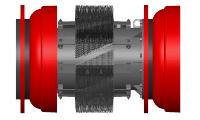

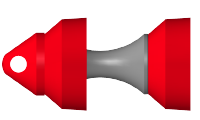

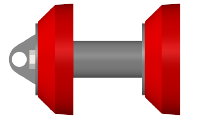

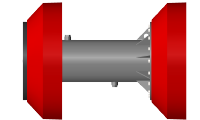

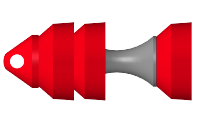

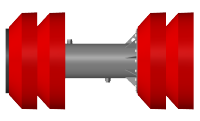

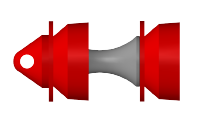

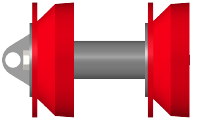

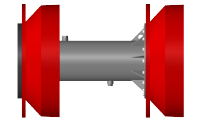

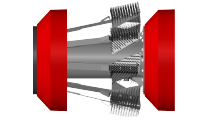

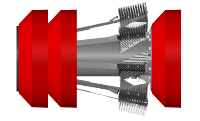

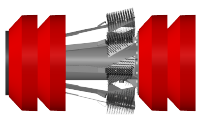

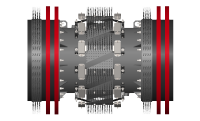

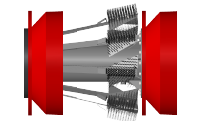

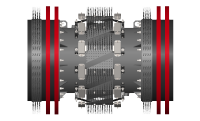

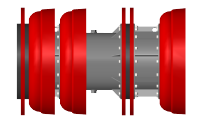

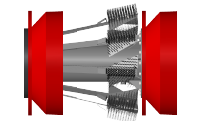

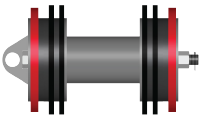

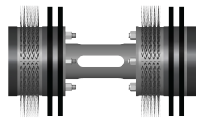

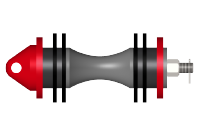

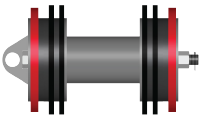

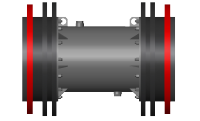

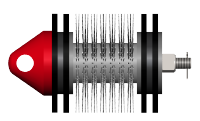

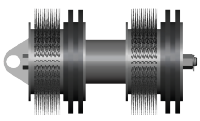

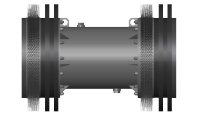

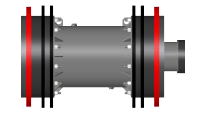

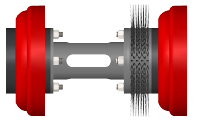

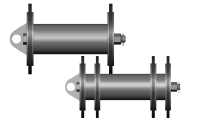

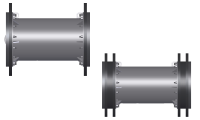

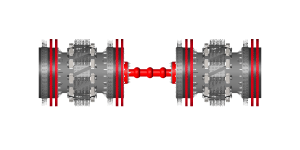

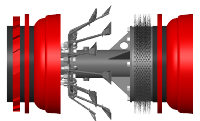

Structure: Mandrel pigs typically consist of a central mandrel or body that is reinforced with metal and surrounded by various cleaning elements, such as brushes, scrapers, or foam discs.

Design: They are often cylindrical and can vary in size to accommodate different pipeline diameters.

Features

Mechanical Cleaning Components: Equipped with scrapers or brushes that actively remove buildup and debris from the pipeline walls.

Robust Construction: Made from durable materials to withstand the harsh conditions often found within pipelines.

Multiple Configurations: Available in various designs and configurations to meet specific cleaning needs and pipeline conditions.

Debris Removal: Effective for cleaning the interior of pipelines by scraping away deposits, such as wax, scale, or rust.

Preparation for Inspection: Often used before conducting pipeline inspections to ensure that the internal surfaces are clean and free of obstructions.

Flow Assurance: Helps maintain optimal flow rates by removing blockages and buildup, thus preventing operational issues.

Enhanced Cleaning Efficiency: The mechanical action of scrapers and brushes allows for thorough cleaning compared to foam pigs alone.

Versatility: Suitable for a wide range of pipeline materials and applications, including oil and gas, water, and chemical transport.

Improved Pipeline Integrity: Regular use can extend the life of pipelines by preventing corrosion and buildup that can lead to failures.

APPLICATION

Oil and Gas Industry: Used for maintaining flow lines, gathering systems, and transmission pipelines.

Water and Wastewater Treatment: Useful in maintaining the efficiency of water distribution and treatment systems.

Chemical Processing: Helps ensure the integrity and performance of pipelines used for transporting various chemicals.

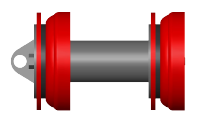

UC2 (2-4″)

UC2 (6-14″)

UC2 (16-48″)

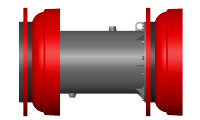

UC3 (2-4″)

UC3 (6-14″)

UC3 (16-48″)

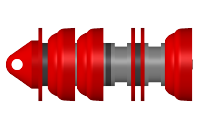

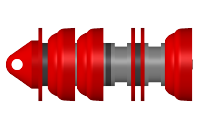

UC4 (2-4″)

UC4 (6-14″)

UC4 (16-48″)

DCD (2-4″)

DCD (6-14″)

DCD (16-48″)

XF (3-4″)

Scraper Cup

XF (6-14″)

XF (16-48″)

UT-UC2 (6-14″)

UT- UC3 (6-14″)

UT-UC4 (6-14″)

UT-XF (6-14″)

UT-DCD (6-14″)

UTR-SC2R (6-14″)

UTR-SC3R (6-14″)

UTR-SC4R (6-14″)

SC2R (3-4″)

SC2R (6-14″)

SC2R (16-48″)

SC3R (3-4″)

SC3R (6-14″)

SC3R (16-48″)

SC4R (3-4″)

SC4R (6-14″)

SC4R (16-48″)

DC2R (6-14″)

DC2R (16-48″)

DC3R (6-14″)

DC3R (16-48″)

DC4R (6-14″)

DC4R (16-48″)

UC2X (16-48″)

UC3X (16-48″)

UC4X (16-48″)

DCDX (16-48″)

UM2 (3-4″)

UM2 (6-14″)

UM2 (16-48″)

UM3 (3-4″)

UM3 (6-14″)

UM3 (16-48″)

UM4 (3-4″)

UM4 (6-14″)

UM4 (16-48″)

DMD (3-4″)

DMD (6-14″)

DMD (16-48″)

UM2X (16-48″)

UM3X (16-48″)

UM4X (16-48″)

All Urethane Products

DMDX (16-48″)

Bi-Directional Products

Scraper Cup Products

Conical Cup Products

UT-ED (6-14″)

UTR-EDR (6-14″)

ED (2-4″)

ED (6–14″)

ED (16–48″)

EDR (3-4″)

EDR (6-14″)

EDR (16-48″)

EDX (16-48″)

EDXR (16-48″)

Bi-Directional

EDXR Dual Body (16-48″)

MDK (16-48″)

UT Mandel Option 6-14″

MD2 & MD4 (3-14″)

MD2 & MD4 (16-48″)

UT Filming Pig

(8-14″)

UM Filming Pig

(16-42″)

JC3 (2-4″)

JC3 (6-14″)

JC3 (16-48″)

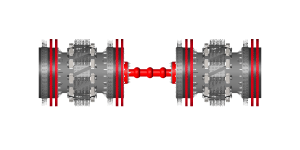

Dual Body Configuration

KNIFE PIG (16-48″)