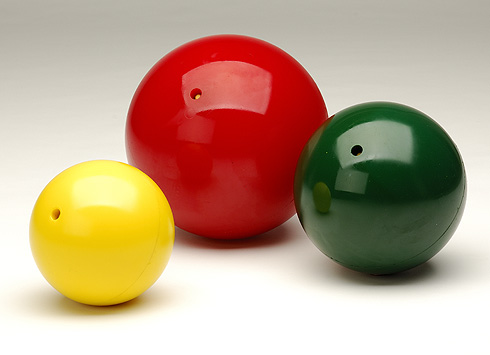

Pipeline Spheres are an effective way to separate or batch products, as well as meter proving and pipeline evacuation. The sphere is also available in FDA Food Grade Material. The Spheres are inflated with a combination of water glycol mix.

Solid and inflatable polyurethane spheres are manufactured in a range of durometers for pipeline and meter prover applications. Neoprene, Nitrile and Viton spheres are also available for special applications. To achieve the maximum performance Girard inflatable spheres must be properly filled and sized. Specific applications will determine the most effective sizing and filler fluid to be used.

ELITE spheres are available up to 36” and inflatable spheres incorporate a method of manufacture to ensure a monolithic joint free sphere. Ancillary accessories include sphere sizing rings, sizing tapes, inflation tools, sphere lifting tools, sphere transportation cassettes, storage nets and hammocks. ELITE also offers an innovative and unique patented storage coating to protect from UV and humidity degradation and attack.

Pressure Balance Sphere is yet another innovative product which has been developed by ELITE for a major gas line operator. The pressure balance sphere is designed to eliminate the time (up to 12 hours in some cases) required to dissipate any ingresses gas collected during service. It also removes the risk of over inflation and faulty valves and seal plugs. Service costs are eliminated as there is no need for a filling medium and therefore filling and emptying of the sphere are not required.

spheres are used for separating various products such as gasolines, fuel oils, crude oils, jet fuels, and other petroleum products transported through a pipeline. Product integrity is maintained while navigating tees and ells.